Application case of self-cleaning air filter in sulfur acid production project of chemical industry

The sulfur acid production process has a very high requirement on the cleanliness of the raw air, which contains a large number of dust particles. When these dust particles enter the sulfuric acid system, the quality of the product will be affected.

When small particles moving at high speed scour and strike the surface of the internal components of the main fan, it will cause wear and deformation of the impeller runner, increase the sealing clearance, affect the airflow movement and reduce the operation efficiency of the equipment. Therefore, it is very necessary to set a self-cleaning air filter in front of the main fan to remove the dust in the atmosphere and ensure that clean air enters the acid production system.

Project overview:

[Customer coordinates] Malaysia

[Industry] Chemical industry

[Equipment used for] Sulfuric acid production project

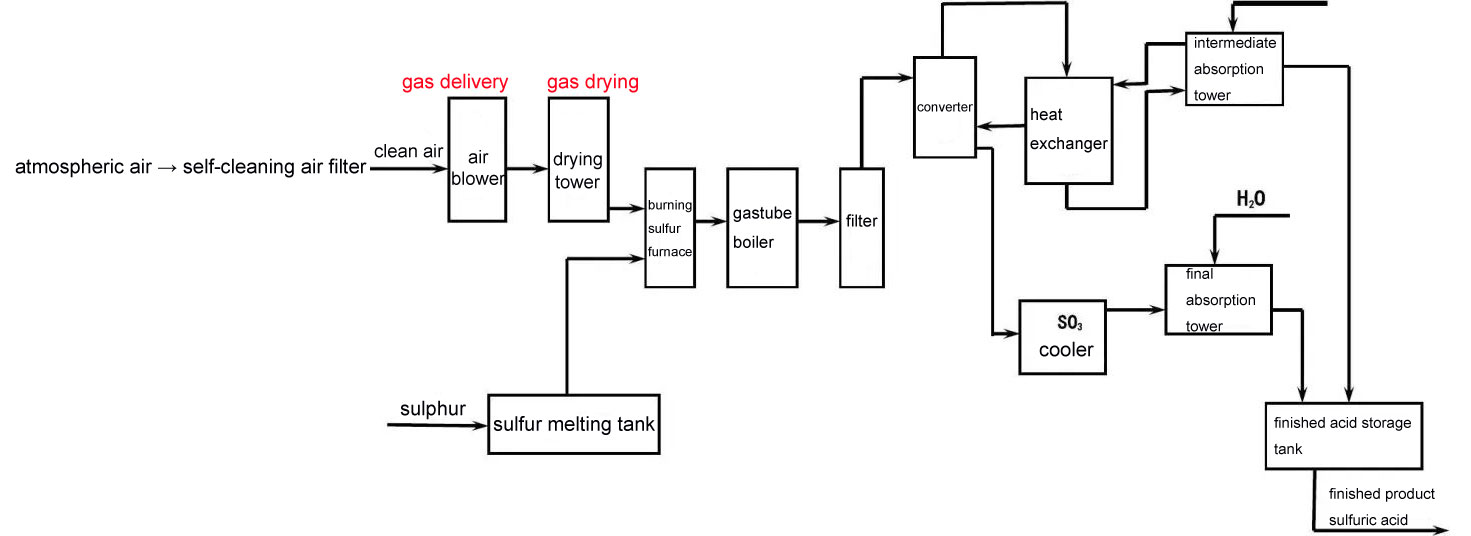

[Process steps] The air filtered by self-cleaning air filter → drying tower → blower → sulfur furnace → other steps of acid production

The performance parameters:

[Treated air volume] 6000m³/min

[Filter area] 7000㎡

[Equipment resistance] <600PA

[Blowback pressure] 0.4 ~ 0.6 MPA

[Filter efficiency] 2um/99.99%

[Air filter cartridge] 280pcs air filter cartridges 325*1000mm (American HV composite fiber material)

Device configuration:

The project uses LEFILTER brand LFZK-6000 self-cleaning air filter, including initial filter mesh, high efficiency filter element, self-cleaning ash system, imported PLC control cabinet, clean air chamber, access door, platform and ladder, etc.

Self-cleaning AIR FILTER is a new type of HIGH efficiency air filter with automatic ash cleaning function, widely used in industrial gas turbine, blast furnace blast, air compressor, etc., especially suitable for high dust concentration environment and strict air purification index of gas equipment as a matching.

Delivery:

The whole process service:

Pre-sale:

*Can guide the equipment selection according to the special needs of customers

*Free field survey, issue customized process plan

Sale:

*Strict implementation of quality standards, factory product quality assurance

*Strictly implement delivery standards and provide logistics and transportation information

After-sales:

*Free to provide equipment installation, debugging and other technical guidance

*Provide equipment operation, maintenance and other technical training

More Project Cases:

01) Application of self-cleaning air filter in biochemical industry

02) COAL MINE GROUP CARBON plant dust removal equipment renovation project site

03) Dust COLLECTION AND TREATMENT PROJECT OF A CHEMICAL INDUSTRY

04) A sign manufacturing company waste gas treatment project