In the high-temperature and high-pollution environment of steel mills, filters have to utilize thick stainless steel cartridges to cope with the test of continuous high temperatures. The sealing structure of the cartridge and filter element can effectively block the hot high-temperature airflow penetration and prevent heat conduction to the internal components. In such a harsh environment, steel mill filters need not only to be able to efficiently filter contaminants, but also to have sufficient life and reliability. Sophisticated multi-layer construction and multiple monitoring are required to meet these requirements.

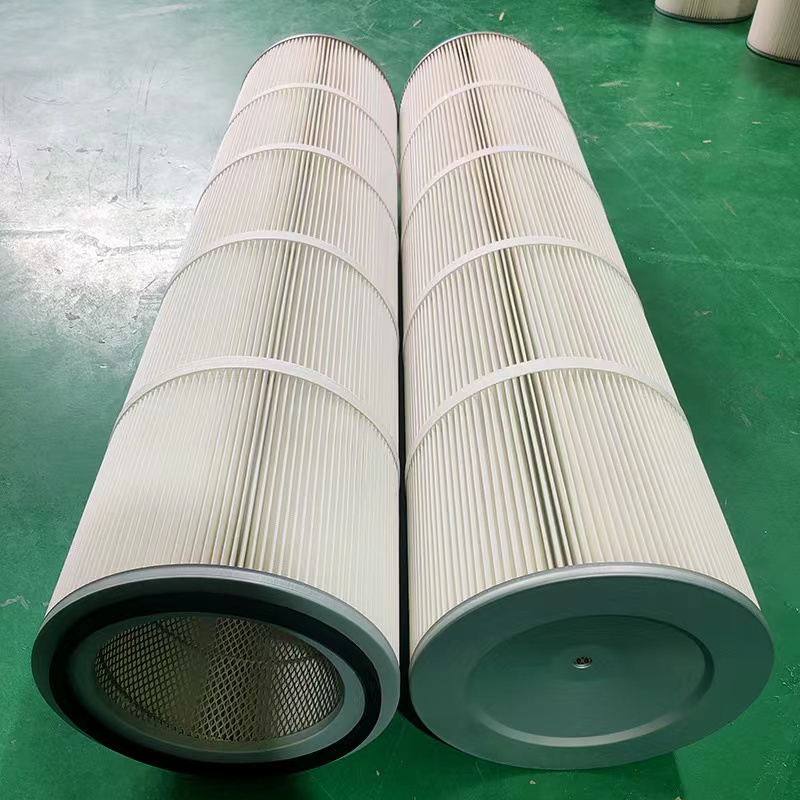

Each cartridge unit is removable, making the filter easily replaceable. But that's not enough. The internal cartridges rely on multiple designs to keep them operating efficiently: the cartridges are constructed of multiple layers of slit stainless steel mesh as fine as 0.3 millimeters, and the primary layer, which has a spacious mesh but is large enough to catch large deposits, protects the intermediate layer. Through the digital pressure sensor to know the filter pressure changes in real time, and then linked to the pre-set cleaning and replacement curve, the filter can be timely and autonomous alerts.This multi-layer structure allows the filter to achieve a filtration efficiency of 99.99%.

Each cartridge unit is removable, and this structural design makes the filter easy to replace. But this is not enough.

The filter mesh also requires special ultra-durable design. Not only does the mesh have to be molecularly fine, but it also has to be treated in a special way to achieve extremely high heat and corrosion resistance. This requires high-end materials and processes.

Technical details and performance indicators of the filters.

Temperature: the maximum working temperature that can be withstood, generally stainless steel cylinder plate filter can reach 350°C or more.

Pressure drop: the pressure difference of the airflow after filtration, which represents the filtration efficiency. Digital differential pressure gauge can be displayed in real time.

Efficiency: general ultra-fine stainless steel filter element mesh ≤ 0.3 mm, up to 99.99% filtration efficiency.

Filter element material: stainless steel wire mesh is the most high-temperature-resistant, after special treatment to obtain ultra-high heat and corrosion resistance.

Filter life: multiple structures to extend the life of the primary layer of loose mesh to capture large particles, help the intermediate layer of filter element use.

Control system: network control and remote monitoring of the level of intelligence.

Filter area: represents the filter specification and air flow rate.

Related Products